Dip-Spin Coating Technology: High Speed, High Protection, Maximum Efficiency

In modern production, it is no longer enough to just make a good coating; it also needs to be fast, economical and environmentally friendly. As Erkap, we have implemented one of the most efficient coating methods,Dip-Spin technology in order to achieve these three goals at the same time.

What is Dip-Spin?

Simply put, the parts are immersed in the coating bath in special baskets (“dip”), then rotated at high speed to remove excess material (“spin”).

Thanks to this two-stage process, an equal film thickness is applied to every point of the surface and the material waste is prevented.

In short: minimum waste, maximum protection.

What are its advantages?

Dip-Spin method, especially It provides great convenience in coating small and many parts (such as bolts, nuts, washers, springs).

Coating is applied to each part in equal thickness.

No drops, accumulations or passivation marks are formed.

The chemical used is kept at the optimum level, reducing costs.

Production time is shortened, cycle time is faster.

It is environmentally friendly and advantageous in terms of waste management.

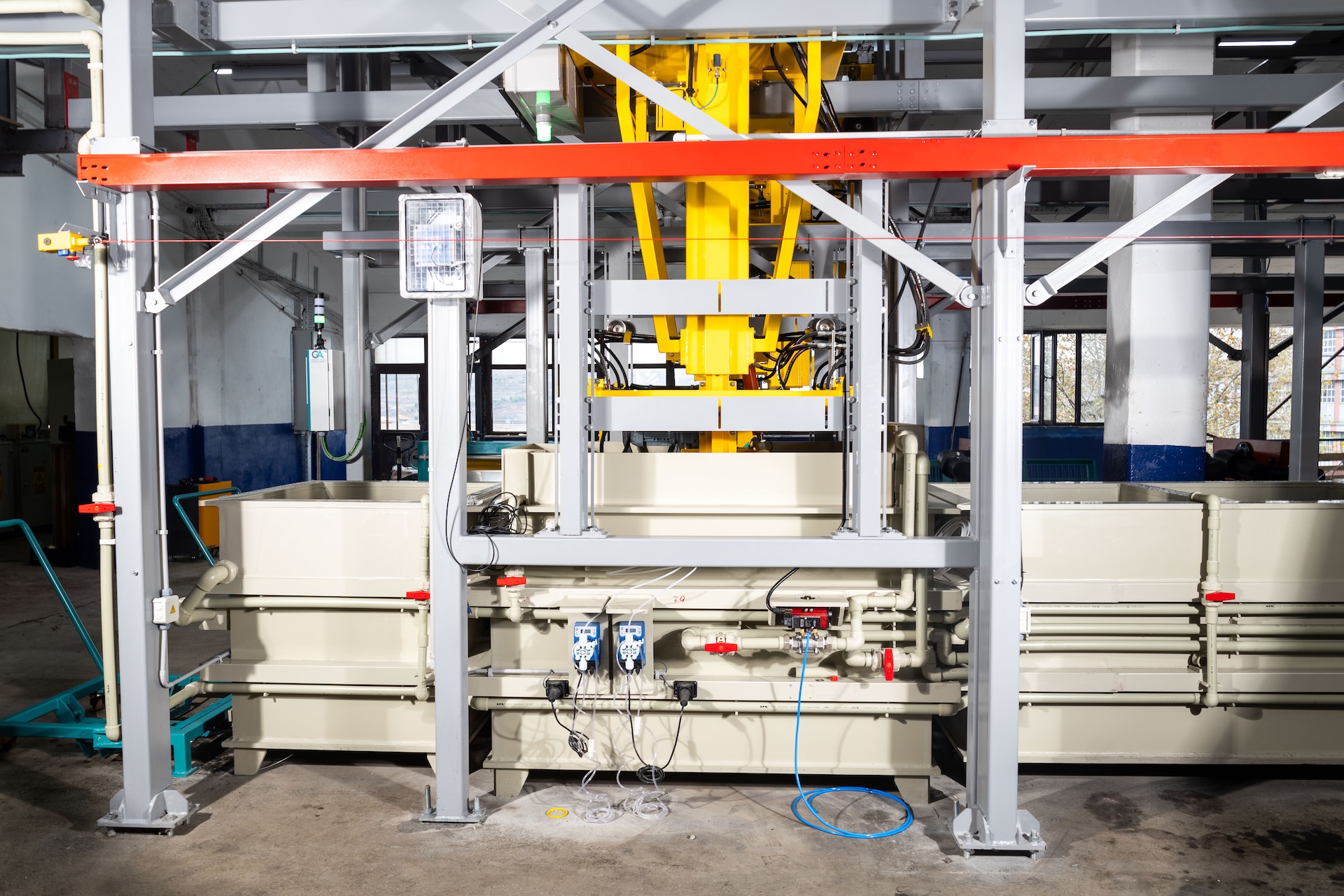

At Erkap, we manage this process withfully automatic controlled systems and subject each batch tofilm thickness and corrosion resistance tests data-start="1674" data-end="1677">

Which parts is it suitable for?

Fasteners (bolts, nuts, screws)

Spring and clip type parts

Small metal components

Parts requiring surface protection before complete assembly

The most powerful aspect of Dip-Spin is that even parts with complex geometries receive equal surface protection in one pass.

Erkap’s The difference

For us, Dip-Spin is not just a process, it is a holistic solution approach.The viscosity, immersion time, centrifuge speed and curing parameters suitable for each product group are determined separately.

In other words, the corrosion resistance, friction resistance and other properties required by your parts are determined separately.